Maize drilling may not yet seem a distant memory… but with the recent warmer weather, we should be looking towards maize harvest.

Assessment of dry matter

Predicting the likely harvest date of your maize crop is an essential part of harvest preparation. The recent warm weather means that the maize crop continues to push through its growth stages. Assessing the dry matter of your maize and using dry down rates will help you predict the potential harvest date of your crop.

You should aim for the dry matter of your crop to be within the target range at the point of harvest. The target dry matter percentage for maize is between 30-35%. This applies to livestock maize and maize for biogas, although biogas plants usually expect a wider range (30-38%) to reflect a more extended harvest campaign.

When commencing harvest, it is advisable to follow varietal maturity and start chopping with the fastest-maturing varieties. You should also aim to complete harvest before varieties reach 38% or more dry matter, this will help maintain the quality of silage.

Methods for assessing Dry Matter

There are several different ways that you can measure your maize dry matter:

The Milk Line Test:

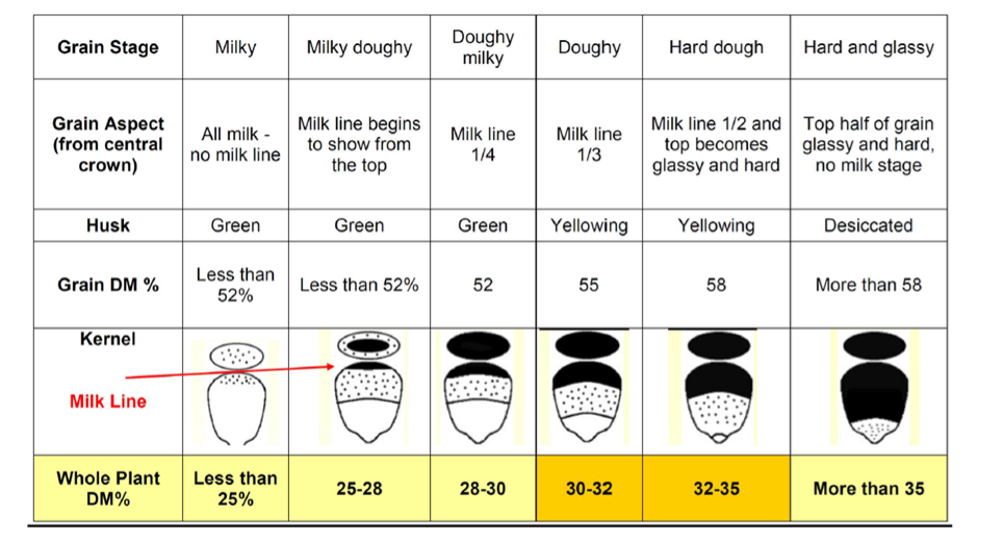

The ‘in-field’ test is known as the ‘Milk Line Test’. This test looks only at the grain and then judges the overall DM of the plant based on the line where the ‘milk’ meets the starch. See the guide in the pictures to the left.

The Milk Line test method involves taking a randomly selected representative cob and snapping it in half. Within a field there will be natural variation in the cob; getting a representative cob is essential for this test. Remove a kernel from the cob and run your fingernail along the length of the kernel, starting at the flat/dented end and working towards the end that was attached to the cob. Note the point where the solid starch ends, and the liquid milk begins. To hit target DM, you are aiming for the milk line to be ⅓ to ½ way down.

Oven-based Testing:

Whole plant dry matter testing can be done in a microwave, oven or, as researched by the MGA, in an air fryer. The following calculation can be used to work out the DM% of your sample:

Dry (post oven) weight (g) ÷ Original fresh weight (g) × 100 = Dry Matter percentage (DM%)

Microwave oven – Dry the sample in the microwave for ten minutes and then pause to stir. Dry for another ten minutes and then stir again. After this, dry for only five minutes and weigh the sample. Record this weight and then return the sample to the microwave for a minute or two at a time, weighing at each interval. When you get two consecutive weights the same, your sample is dry. Record this weight as the final dry weight and perform the calculation above. Keep a close eye on the maize through this process. If it dries out too much, it may smoulder and catch alight! You can put a glass of water in the microwave alongside the sample to reduce the risk of over-drying.

Oven – Dry in an oven for 16 hours at 105°C. Weigh the product again and record the dry weight. This is a very reliable and accurate method of assessing the dry matter. However, it is time-consuming and will not give you a quick result.

Air fryer – This is the preferred method of oven-drying a sample at the MGA as it is less volatile than the microwave method but is much quicker than the full oven procedure. For a small sample, we have found it possible to dry at 110°C for only 40 minutes, but 90 minutes would be appropriate if the air fryer is fuller. As with the microwave method, if you are unsure of timings, weigh the sample and then dry for another few minutes and weigh again. If the weight remains the same, it is fully dry.

Chop quality

Maize for livestock is chopped to around 12mm, with a longer chop of about 18 – 22mm used in some circumstances. Individual choice of chop length will depend on how the maize is being used. Maize for biogas tends to be chopped more finely at 5-8mm as this allows a greater surface area for the microbes to work on.

Grain processing

Making sure the kernels are broken is an important quality parameter. This ensures maximum energy output from the maize and that the kernels do not become undigested. The kernel processing unit in the forager should be set up depending on the maturity of the grain. When maize crops reach a higher degree of maturity with large, hard kernels, it is essential that processing is done adequately. If the kernels are hard, they must be well crushed or broken into 3-4 pieces.

Additive

Maize ferments well and does not typically require an additive to establish a stable fermentation. After an assessment, additives may be added to give better aerobic stability and keep the quality of the silage, to improve digestibility, intake and feeding value.

Clamping

Maize silage needs to be made quickly, well consolidated, and completely sealed to allow anaerobic fermentation to occur. Ideally, the weight on the clamp should be at least 25% of the hourly fill rate, i.e. 100t/hr fill rate requires 25t of machines on the clamp. Fill the clamp in thin layers using a shallow wedge. To ensure that the whole clamp, including the shoulders, is well compacted, consolidate thoroughly from the bottom, and fill and roll the clamp continually.

Sheeting

Good sealing of the clamp is vital. Side sheets, as well as an oxygen barrier sheet, should be used. This layer is thin enough to be sucked onto the maize surface as oxygen is used up but tough enough to remain intact when laid out. Weigh down the top with plenty of gravel bags. Continue to monitor the clamp throughout the year and repair or replace sheets if they become damaged to minimise aerobic spoilage.

IF YOU COULD DO WITH ADVICE ON CROP QUALITY, GROWTH STAGE, HARVEST or CLAMPING – WE CAN HELP

CONTACT US FOR A CONVERSATION